| Home | Company | Products | Support | Download | Employment | Contact | Chinese |

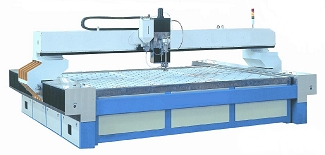

Waterjet Cutting System Model Number: WC5WA3020H420Mpa (60,000 psi), 2000x3000mm ( 6'x10')

Full abrasive waterjet cutting system consists of high pressure pump, cutting table with hopper, and CNC controller.

CNC cutting table:

The table consists of water tank, X-Y motion system, Z axis motion, cutting head assembly, and abrasive reservoir with adjustable abrasive feed control. Overpass style. Cutting table working area size: 78"x130" (2000x3000mm). Water tank is made of stainless steel.

X-Y motion system consists of servo motor and driver, ball screw and precision linear guide. Z-axis motion is driven by AC motor with speed reducer. X-Y position accuracy is 0.06mm, repeatability is 0.03mm. Over all cutting accuracy is at max 0.10mm. This machine can cut all kinds of metal, marble, granite, glass, ceramic tile, rubber, plastic, virtually any materials. This machine can cut metal up to 100mm thick. Under water cutting is available with this model to reduce noise and splash.

CNC controller CNC controller consists of advanced industrial grade computer and specialized software running on the Microsoft windows platform. The controller is capable of simultaneous X-Y axis interpolation movement. Fast accelerate or decelerate motion and high speed travel from point to point. Simulation without motion or dry run with axis motion but no jetting of water/abrasive are features included. Error stop and trace repeat are also very useful features. Out of range warning and hard stop to prevent damage capability are embedded in the system. Emergency shut off switch is provided. Remote control is provided to control the motion of X-Y-Z axis when operator is away from the controller tower.

DXF file compatible:

The

controller is compatible to dxf file format. Users can save design drawing in

.dxf from AutoCAD and read the file into the controller. Controller will post

the dxf file to G-code. The controller can also read G-code generated

from other

Advanced

CAD/CAM software (optional): for design drawing, define machine path and

lead in/out, nesting, tool offset, and generate G code. Features are similar to

AutoCAD, and with rich features of

Automatic abrasive feeder:

| |||||||||||||||||||||||||||||||||||